From a microscopic perspective, the good scratch resistance of BOPP Protective Film can be attributed to several factors related to its material properties and structure:

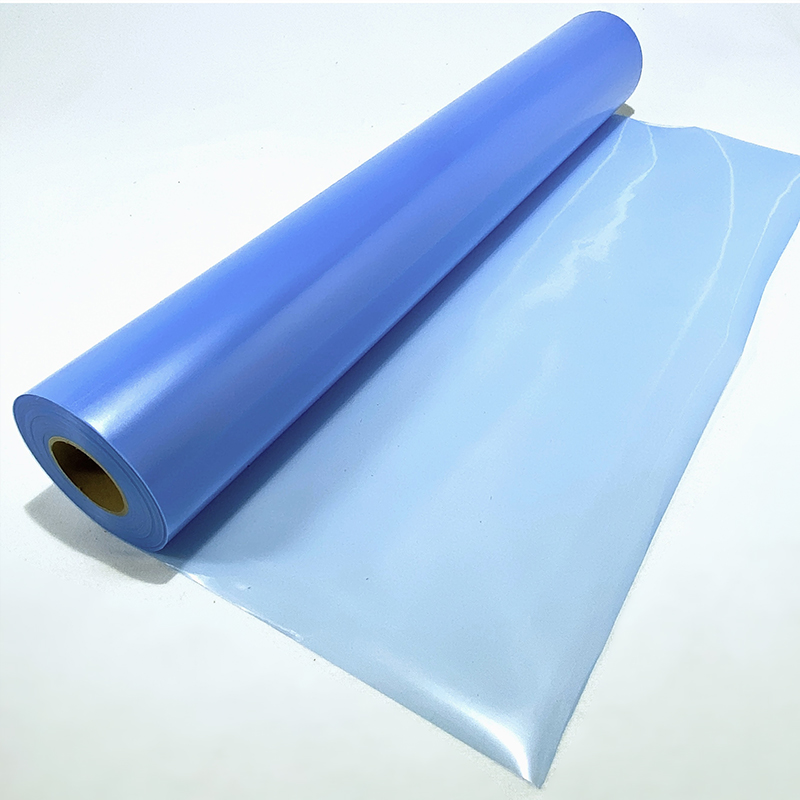

1. Hardness and Strength of BOPP Material:

BOPP is a polymer film that exhibits a certain level of hardness and strength at the microscopic level. It is inherently more resistant to abrasion and scratching than many other materials. The microstructure of BOPP includes tightly packed polymer chains, making it durable and less prone to surface damage.

2. Smooth Surface Texture:

BOPP films typically have a smooth and even surface at the microscopic level. This smoothness minimizes the contact points between abrasive particles and the film surface, reducing the potential for scratches.

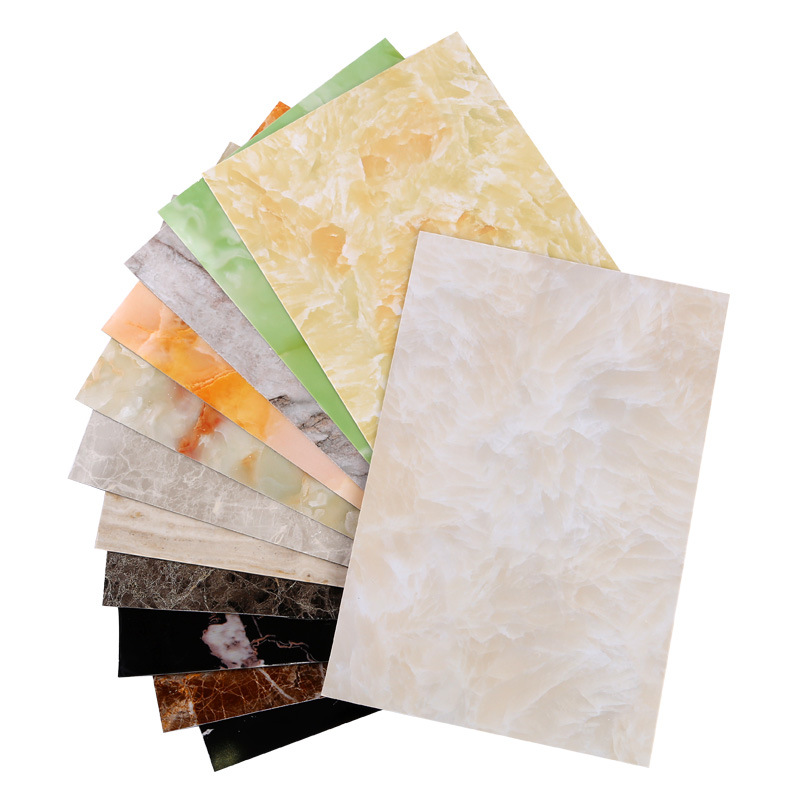

3. Adhesive Layer Properties:

BOPP Protective Film includes an adhesive layer that bonds the film to the protected surface. The adhesive layer is designed to distribute and absorb forces at the microscopic level, preventing sharp objects or particles from penetrating or scratching the underlying surface.

4. Impact Resistance:

While not a microscopic property, BOPP films are engineered to disperse and absorb impact forces at the microscopic level. This can prevent the formation of microcracks or scratches when the film is subjected to mechanical stress or contact with foreign objects.

5. Uniform Film Thickness:

The film is manufactured to have a consistent thickness across its entire surface. This uniformity ensures that there are no thin or weak areas that could be more susceptible to microscopic abrasions.

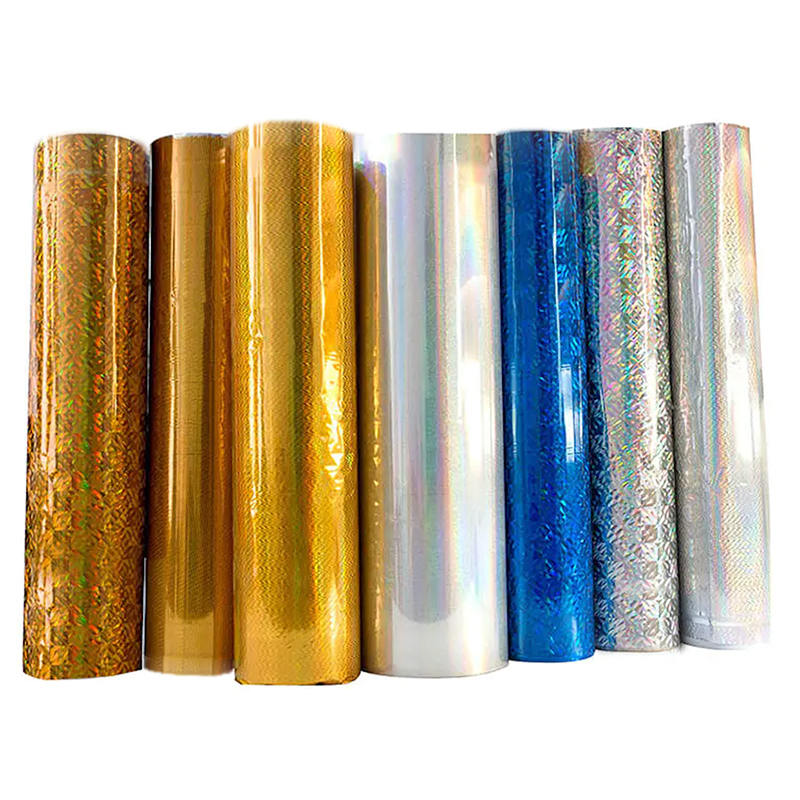

6. Durability of Ink or Coating Layers:

In some cases, BOPP Protective Films may have ink or coating layers for specific applications, such as branding or coloration. These layers are designed to be durable at the microscopic level, resisting wear and scratches.

7. UV and Chemical Resistance:

BOPP films often incorporate additives that provide UV and chemical resistance at the microscopic level. This resistance helps protect the film's surface from degradation and damage that can lead to microscopic scratches.

8. Controlled Material Properties:

The manufacturing process of BOPP films allows for precise control over material properties, ensuring that the film is engineered to be resistant to wear and damage at the microscopic scale.

The good scratch resistance of BOPP Protective Film is the result of a combination of material properties, surface characteristics, and engineering that work together to protect the underlying surface from microscopic abrasions and damage. These factors collectively contribute to the film's ability to maintain a pristine appearance and prevent surface scratching, even under various environmental and handling conditions.

English

English

WeChat

WeChat WhatsApp

WhatsApp