A protective layer is often added to brushed aluminum film to enhance its durability, resistance to wear, and environmental protection. The type of protective layer can vary depending on the manufacturer and the specific requirements of the application. Here are some common types of protective layers that can be added to brushed aluminum film:

1. Clear Polyester (PET) Film:

- Clear polyester is a popular choice for a protective layer. It provides good scratch resistance and protects the brushed finish from abrasion, moisture, and UV exposure.

2. Clear Polyurethane (PU) Coating:

- Polyurethane coatings are known for their toughness and durability. They offer excellent protection against scratches, chemicals, and UV radiation.

3. Clear Polyethylene (PE) Film:

- Polyethylene films can be used as protective layers. They are typically thinner than polyester or polyurethane films but still offer some level of protection.

4. Clear Epoxy Resin Coating:

- Epoxy resin coatings are used for applications where a high level of protection is required. They are tough and resistant to chemicals, making them suitable for harsh environments.

5. Anti-Graffiti Coating:

- In some cases, brushed aluminum film used in public spaces or high-traffic areas may have an anti-graffiti coating. This coating makes it easier to remove graffiti and other markings without damaging the underlying film.

6. Self-Healing Coating:

- Some advanced protective layers are designed to be self-healing, meaning they can repair minor scratches and abrasions over time when exposed to heat or sunlight.

7. Anti-Fingerprint Coating:

- For applications where smudges and fingerprints are a concern, anti-fingerprint coatings can be applied to maintain a clean appearance.

8. Anti-Reflective Coating:

- In applications with strong lighting or displays, anti-reflective coatings can reduce glare and improve visibility.

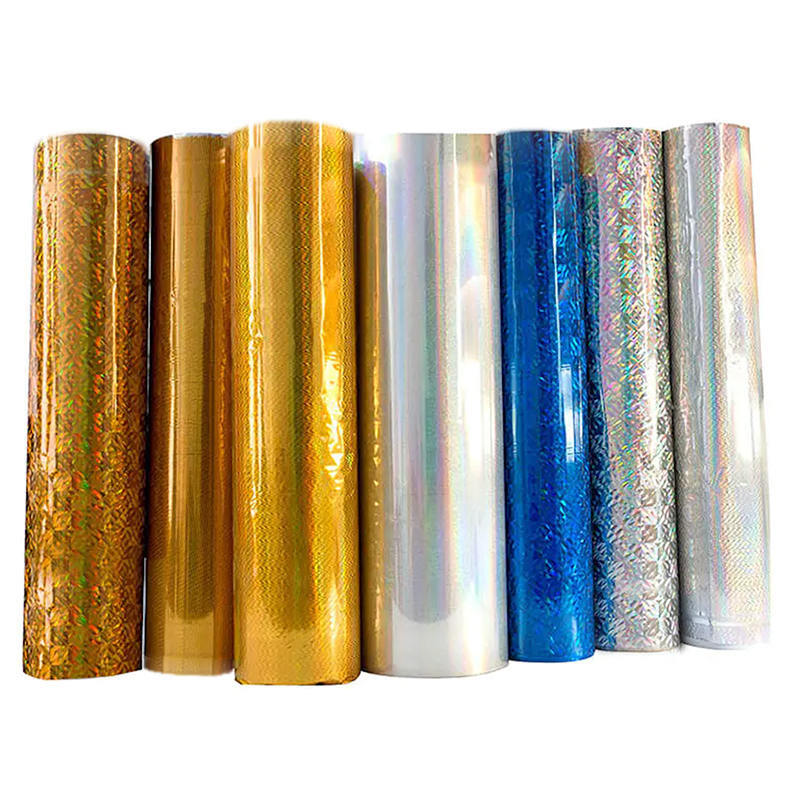

9. Matte or Textured Finish Coating:

- While not purely protective, matte or textured coatings can alter the appearance of the brushed aluminum film, giving it a different aesthetic or tactile quality.

The choice of protective layer depends on factors such as the intended use of the film, environmental conditions, budget constraints, and desired aesthetic properties. Manufacturers often offer a range of options to meet the specific needs of their customers, and custom coatings can also be applied based on project requirements.

English

English

WeChat

WeChat WhatsApp

WhatsApp