The post-metallization process of metallized PET (Polyethylene Terephthalate) film involves additional steps that are performed after the metal coating has been deposited onto the film's surface. These steps are aimed at enhancing the film's properties, appearance, and performance for specific applications. Here are some common post-metallization processes for metallized PET film:

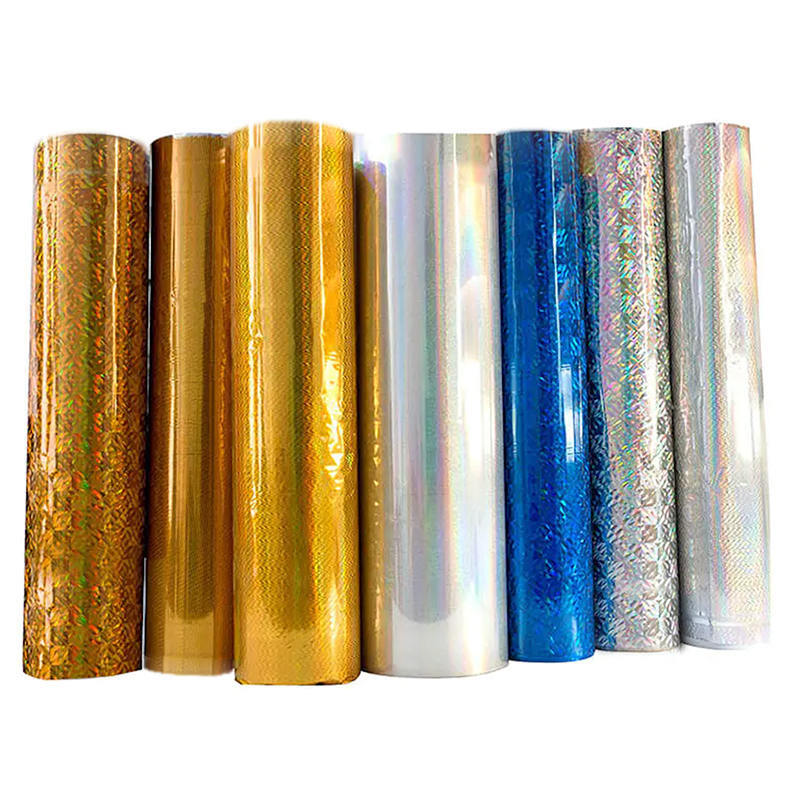

1. Coating or Lacquering:

- Applying a clear or colored protective coating or lacquer over the metal-coated surface to improve durability, scratch resistance, and barrier properties.

- Enhancing the film's aesthetics by adding gloss, matte, or other visual effects.

2. Printing and Decoration:

- Printing graphics, designs, text, or branding onto the metal-coated surface using techniques like flexography, gravure printing, or digital printing.

- Utilizing the reflective and visually appealing properties of the metal coating to create unique and eye-catching designs.

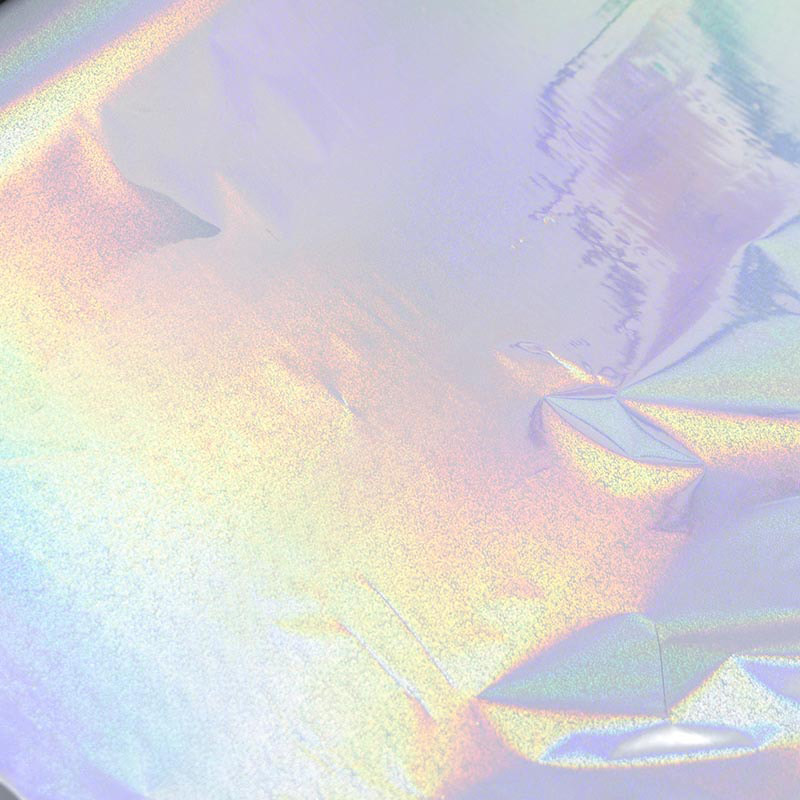

3. Embossing and Texturing:

- Creating embossed or textured patterns on the metallized surface for added visual and tactile appeal.

- Enhancing the film's aesthetics and differentiation in packaging and labeling applications.

4. Adhesive Application:

- Applying adhesives or coatings that improve the bond strength between the metallized PET film and other materials in lamination or assembly processes.

5. Slitting and Cutting:

- Slitting the metallized PET film into narrower rolls or cutting it into specific shapes and sizes according to the requirements of the intended application.

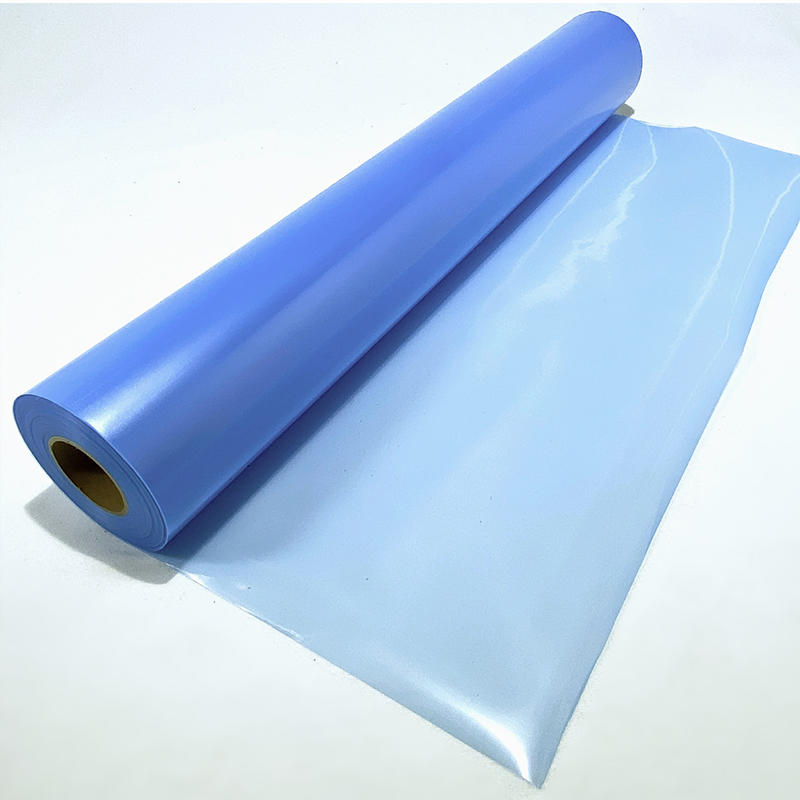

6. Laminating:

- Bonding the metallized PET film with other substrates, such as paper, board, or other plastics, to create composite materials with enhanced properties.

7. Conversion and Forming:

- Converting the metallized PET film into final products, such as pouches, bags, labels, wraps, or other packaging solutions.

- Forming the film into 3D shapes or structures using techniques like thermoforming or vacuum forming.

The choice of post-metallization processes depends on the intended application of the metallized PET film and the specific properties or features desired. Each post-metallization step contributes to the final characteristics of the film and ensures that it meets the requirements of various industries and uses.

English

English

WeChat

WeChat WhatsApp

WhatsApp