Metallized PET (Polyethylene Terephthalate) film is commonly used to enhance electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding in various electronic and electrical applications. The key mechanism through which metallized PET film enhances EMI/RFI shielding is by reflecting and attenuating electromagnetic waves. Here's how the process works:

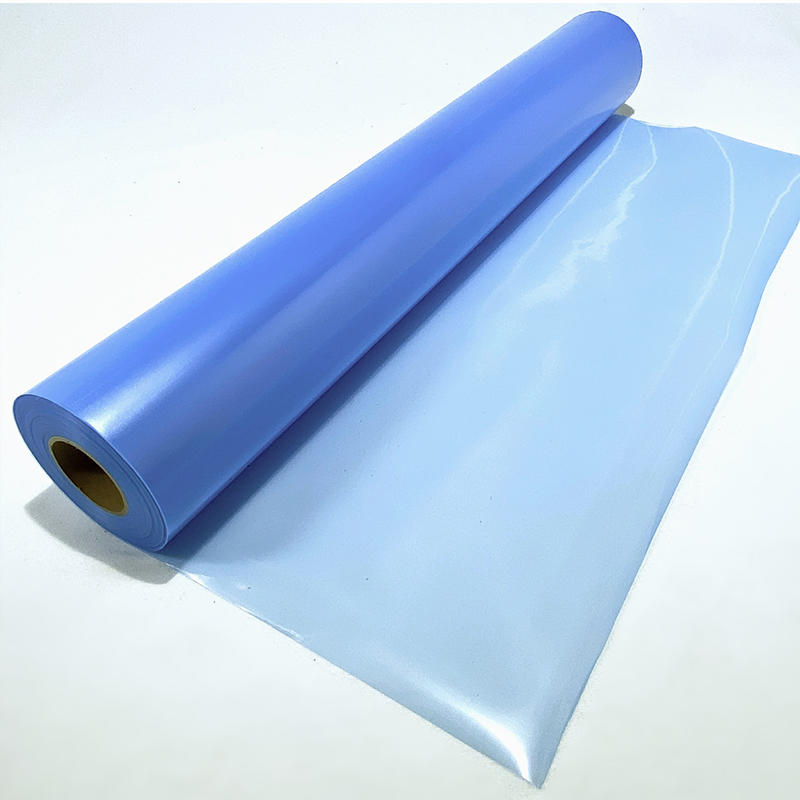

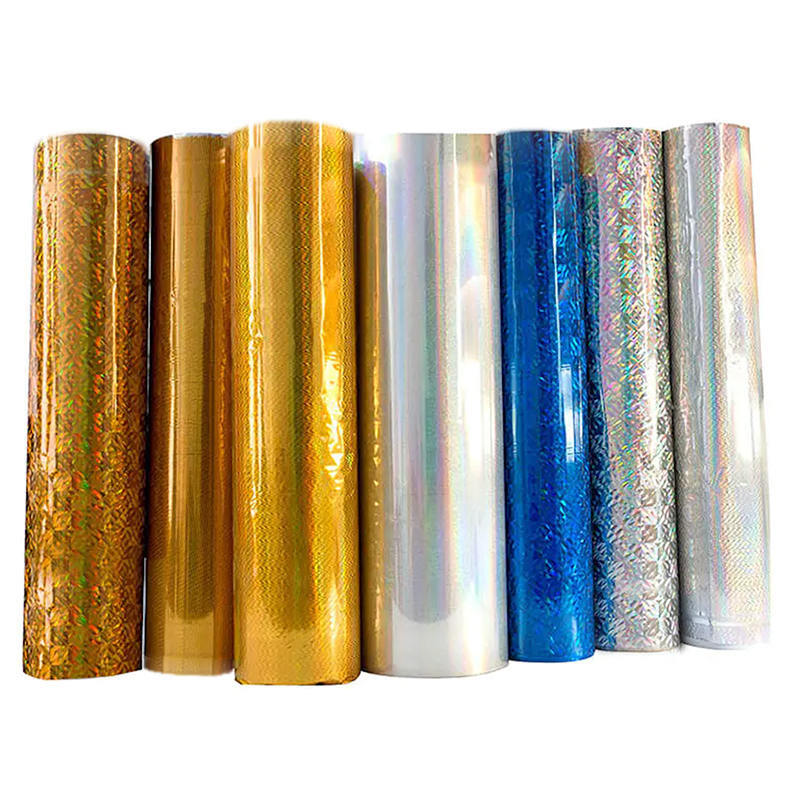

1. Metal Coating: Metallized PET film is coated with a thin layer of metal, typically aluminum, on one or both sides. The metal coating forms a conductive layer that provides a barrier against the penetration of electromagnetic waves.

2. Reflection and Absorption: When electromagnetic waves encounter the metal-coated surface of the PET film, they are reflected and absorbed by the conductive metal layer. This prevents the waves from passing through the film and effectively diverts them away from sensitive components or areas.

3. Conductive Pathway: The metal coating on the PET film creates a conductive pathway that allows any induced currents to flow along the surface of the film rather than penetrating the material. This helps channel and dissipate the electromagnetic energy.

4. Faraday Cage Effect: Metallized PET film can also contribute to creating a partial Faraday cage effect, which is a phenomenon where the conductive material (the metal coating) forms an enclosure that shields against external electromagnetic fields.

5. Shielding Effectiveness: The level of EMI/RFI shielding provided by metallized PET film is determined by factors such as the thickness of the metal coating, the type of metal used, and the frequency of the electromagnetic waves. Thicker coatings and higher conductivity metals tend to offer better shielding effectiveness.

6. Flexibility and Adaptability: Metallized PET film retains the inherent flexibility of plastic films, making it suitable for conforming to different shapes and enclosures. This flexibility allows it to be easily integrated into various electronic devices and components.

7. Dielectric Properties: The PET substrate of the film also contributes to its overall shielding performance. PET has relatively low dielectric constant and loss tangent, which means it does not significantly interact with electromagnetic fields, allowing the metal layer to efficiently reflect and absorb electromagnetic waves.

Metallized PET film is commonly used as a component in flexible EMI/RFI shielding solutions, such as tapes, gaskets, enclosures, and covers. It is particularly valuable in applications where traditional rigid metal shields are not feasible due to space constraints or design considerations. The combination of metallized PET film's reflective and conductive properties, along with its flexibility, makes it an effective and versatile choice for enhancing EMI/RFI shielding in a variety of electronic and electrical systems.

English

English

WeChat

WeChat WhatsApp

WhatsApp